|

Shenzhen Advanced Titanium Technology Co.,Ltd

|

Titanium Connecting Parts Product Product Product

| Place of Origin: | , China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

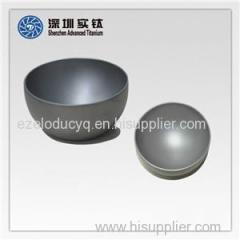

Titanium Connecting Parts,Medical Parts

1.Product name:Titanium connecting parts2:Material and technics1. Material: Grade 5 Titanium2. Technics: Precision casting,Website:http://www.advanced-titanium.com, CNC3. Surface finish: Polishing(mirror), sandblasting4. Surface roughness: Ra 1.65. Casting minimum tolerance: +/-0.1mm6. CNC minimum tolerance: +/-0.01mm7. Inspection: Slide caliper, microcaliper8. Certification: ISO9001:20089. Package: Cartons10. OEM Service: We can produce it according to your drawings or samples.11. Application:Medical parts3.Product specifications:1. Product description of titanium connecting parts :Titanium alloy is an unique and innovative material, which is Light-weight, Low-density, High-strength, Corrosion-resistance, High temperature resistance, Good performance in low temperature, High wear resistance, Small thermal elasticity, Rust-proof, Good process performance, etc., is an ideal structural materials in medical field.2. Application of Titanium Alloy:1) Aerospace Aviation: Titanium impeller, Titanium turbine, Titanium engine blades, Titanium airplane wings/ tails/ skin......2) Military Series: Titanium rocket engine, Titanium connecting parts, Titanium rocket head/ wings/ tails......3) Auto Parts: Titanium connecting rod, Titanium engine parts, Titanium stator, Titanium rotor......4) Medical Service: Titanium bone, Titanium joint, Titanium bridge plate, Titanium femoral head, Titanium heart stents, Titanium medical parts......5) Petrochemical: Titanium valve, Titanium pump......6) Sporting Parts: Titanium golf head, Titanium golf cue, Titanium bicycle pedal, Titanium bicycle frame, Titanium bicycle parts......7) Daily Life: Titanium Arts & Crafts, Titanium Jewelry (ring, bracelets, necklaces...), Titanium watch, Titanium tableware ( chopsticks, knife, fork, cup), Titanium bottle opener, Titanium compound bow......NAMETitanium connecting partsTITANIUM GRADE GR1, GR2, GR5 (TA1, TA2, TC4)STANDARDASTM,GBWEIGHT40gDIMENSION CustomizedSURFACE TREATMENT Sandblasting, Polishing, High-precision CNC machiningTOLERANCE ±0.005mmQUALITY CONTROLIndustry CT Scanning, x-ray technolog, Fluorescence detectionAPPLICATIONMedicalCERTIFICATIONISO9001:20084. Production process of titanium casting: 5. Company information1) Shenzhen Advanced Titanium Technology Co., Ltd specialized in precision casting, sand mold casting, Metal type and centrifugal casting, all kinds of titanium and rare metal, which can supply best OEM service & CNC machining.2) A strong technical team - 1 professor, 3 doctoral engineers and other engineers withmore than 5 years of experience in casting production, which can better satisfy your customized requirements.3) Well educated International sales staffs keep rapid and effective communication.4) With 4,000 square meters factory, complete and mature production line, which can assure the production, delivery time and quality assurance of your orders.Company and Factory Overview8.Certification9. Package: 1) Inner packing: poly bag/tissue paper/EPE Cotton;2) Outer packing: standard export carton, plywood case, plywood pallet;3) Customized package are available

Related Search

Titanium Product

Plastic Product

Metal Product

Safety Product

Baby Product

Electronic Product

More>>